Single-deck valves contain only one layer of poppets, rings, or plates and are typically used in compressor applications where maintaining low fixed clearance is essential. This configuration is commonly found in high-speed compressors and, in certain cases, low-speed compressors as well. In general, when the pressure ratio exceeds 2:1, it is highly probable that most valves in the system will be single-deck designs. While single-deck valves are effective in minimizing clearance, they offer less flow area compared to double-deck or deck-and-a-half valves. As a result, more energy is required to move gas through the valve, potentially impacting overall efficiency.

Deck-and-a-half valves feature two layers of poppets, rings, channels, strips, or plates. They are commonly utilized in low pressure ratio applications, such as natural gas transmission. Compared to single-deck valves, deck-and-a-half valves offer increased flow area, resulting in significantly lower energy requirements for gas passage through the valve. These valves also typically have slightly less fixed clearance than double-deck valves, providing a balanced solution between flow efficiency and clearance optimization.

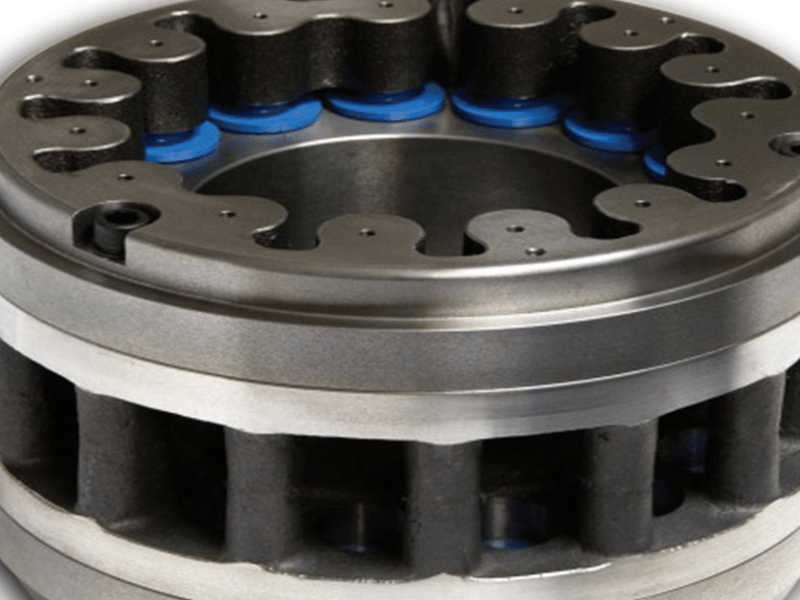

Double-deck valves feature two layers or levels of poppets, rings, channels, strips, or plates. These valves are commonly employed in applications such as natural gas transmission, particularly where compressors operate at relatively low pressure ratios (typically less than 1.5). Compared to single- deck valves, double-deck valves generally offer a greater flow area, thereby reducing the energy required to move gas through the valve. In instances where compressors frequently operate under overloaded conditions, upgrading from single deck to double-deck valves can be beneficial. This change can increase fixed clearance and enhance overall compressor efficiency, effectively aiding in compressor unloading. Due to their relatively high fixed clearance, double-deck valves are generally not recommended for applications with pressure ratios exceeding approximately 2.0, unless their use is necessary to facilitate gas flow into and out of valve cap clearance pockets.

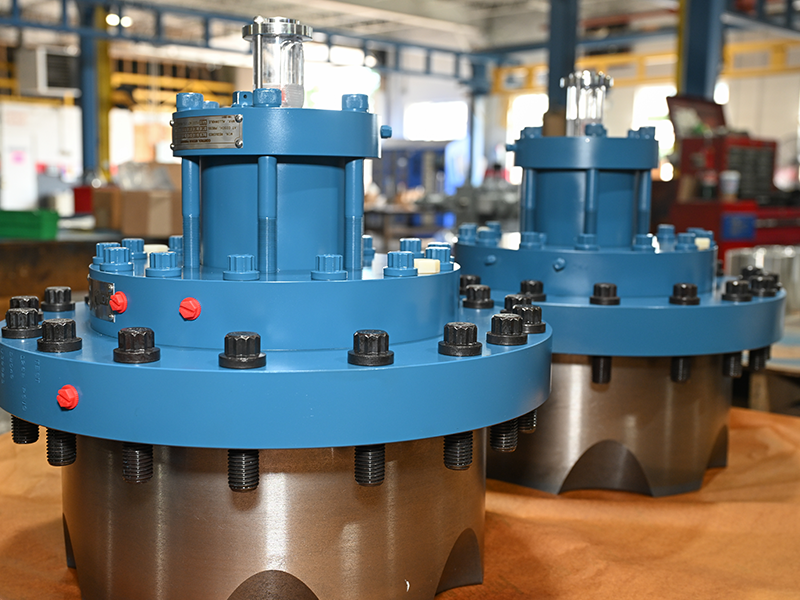

Radial valves manufactured by Cooper’s ACI Services Division offer the highest flow area among all valve types currently available—typically providing two to two and a half times the flow area of single-deck valves. These valves feature poppets arranged to seat on a cylindrical surface. In radial suction valves, the poppets seat on the interior of a sleeve, while in radial discharge valves, the poppets seat on the exterior of a sleeve. The fixed clearance associated with radial valves is comparable to that of double-deck valves. Due to their exceptional efficiency, ACI’s radial valves are particularly advantageous in applications where available valve area is limited. In such cases, these valves can reduce the energy required to move gas through the compressor by 50% or more.