AN EMERGING LEGENDSTM SERIES PRODUCT

DUAL COATED FOR DURABILITY & Environmental friendliness

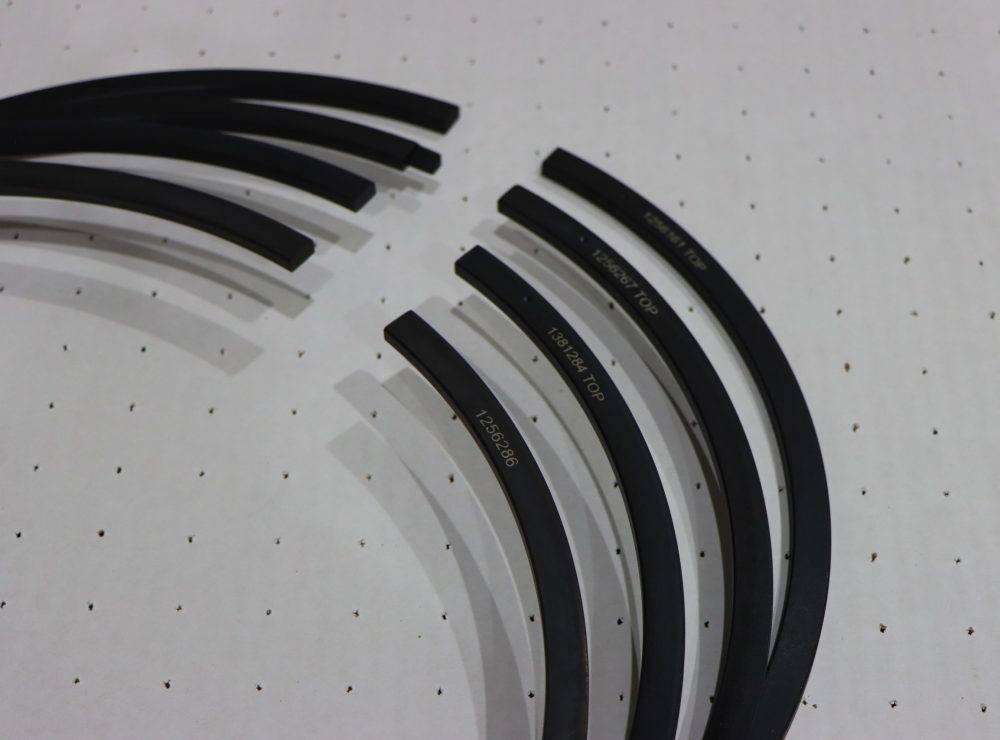

Cooper’s plasma-sprayed power piston rings, dual coated with molybdenum and nickel graphite (Mo2), are offered as an upgrade to traditional ferrox coated rings for large bore integral engines. The Mo2 coating technology was first introduced to large bore diesel engines in the marine industry many years ago and has been applied with great success around the world. Cooper’s Mo2 coated rings reduce risk of start-up and break-in failures, and allows extended time between ring replacements. The Mo2 coated rings are available for large bore, slow-speed engine brands such as Cooper-Bessemer, Clark, Ingersoll Rand, and Worthington.

Cooper is the only engine O.E.M. that manufactures engine power piston rings. These world-class Mo2 rings are produced and stocked in our Houston, Texas manufacturing and distribution center.

Mo2 Coating (hexavalent Chrome Free!)

Piston rings are critical to engine performance. The rings must create an effective seal against the bore and ring groove while operating in a hostile environment of hot, and sometimes corrosive, gases with limited lubrication. A premature failure can be costly, which is why quality piston rings make good sense. By applying a coating on the ring, the wear properties are greatly improved.

The Mo2 coating has two layers: a base layer of molybdenum composite material and a top layer of nickel graphite. Both coatings are applied through thermal (plasma) spraying. Molybdenum-based coatings provide low wear rates and prevent scuffing. Nickel graphite material has the ability to wear in and conform without causing wear or damage to the counter surface. Best of all, there is no hexavalent chrome in our ring manufacturing coatings.

The nickel graphite top layer will remain for the first several thousand hours of run time. When this layer wears off, a second coating layer of molybdenum is exposed, providing excellent wear and scuffing resistance for extended engine life. The coating is applied to a barrel-faced ring for optimal seating-in and lubrication performance.

Mo2 advantages

- Available for all cylinder liner materials

- Anti-scuff

- Long ring life

- Fast, safe break-in and seating

- Barrel-shaped ring profile for better sealing

- Hexavalent chrome-free

Cooper’s extended life power piston rings are an inaugural member of the Emerging Legends™ Series, our portfolio of new products and services that advance the industry and transform Cooper’s traditional way of doing business. Emerging Legends™ serves as a testament to the Cooper commitment of optimizing performance of legacy engines and compressors, helping our customers extend the life of their equipment, and bringing environmentally sustainable solutions to the market.

in-house manufacturing — Genuine O.E.M.-Quality power piston rings

Cooper has spent decades providing technology and engineering services for AJAX engine and compressor upgrades. With our advanced technologies, expertise, and project management experience, we offer AJAX upgrades to reduce engine emissions, increase horsepower, improve efficiencies and reliability of your equipment, and reduce maintenance costs.

To further strengthen our upgrade portfolio for AJAX engines, Cooper acquired HOERBIGER’s Engines Services (HES) division in 2019. Cooper now offers even more upgrade technologies including the HyperLogic™ and ePCC™. The Engine Services team has been offering engine emissions reduction and efficiency improvement upgrades, applicable to all types of AJAX integral engines.

expedited delivery

Our dual coated power piston rings are produced and stocked in our Houston, Texas manufacturing and distribution center for all Cooper O.E.M. and non-Cooper slow-speed engines, assuring the power piston rings you need are available when you need them. Our goal is to have same day or next day delivery service to our customers.

Contact your Cooper sales representative to learn more about dual coated rings and place an order.