enterprise center of excellence (COE)

Cooper is the O.E.M. for the famous line of Enterprise engines and compressors. Enterprise products are deployed globally in gas compression, power generation, marine applications, and nuclear standby. Just like other Cooper products, Enterprise engines have a rich legacy and have been in service since 1917.

Cooper’s facility in Houston, Texas serves as the Enterprise center of excellence (COE) within Cooper’s global support network. The shop is a certified nuclear cylinder head repair facility and is the only certified shop to manufacture new and repaired Enterprise R-4 steel heads for the nuclear industry.

We maintain a stock of Enterprise exchange components to get you back up and running during an emergency breakdown or to perform general maintenance activities. With backing from our dedicated engineering department, our COE in Houston manufactures and refurbishes many of the components in the Enterprise product line.

Our parts, shop, and field service personnel stand ready to provide top of the line quality services for all your Enterprise engine and compressor units, in all applications ranging from pipeline, power generation, marine, and nuclear standby.

enterprise COE Core Capabilities

This location specializes in the following types of service and repair:

- Only certified shop to manufacture and repair Enterprise R-4 steel heads for the Nuclear industry

- Nuclear certified welder and equipment

- Metalizing and tungsten carbide spray coating

- Certified nuclear power head repairs

- Engine block, liner, camshaft, and connecting rod repair

- Comprehensive pump repair

- Compressor cylinder repair

- Compressor piston and rod manufacturing

- CFT compressor ring and rider band manufacturing

- Bushing manufacturing

- Parts warehouse

- Tungsten coating of non-O.E.M. parts

- Project management

enterprise COE specialty machining tools

This location has the following specialty machining tools:

- Welding shop capable of welding Stellite

- 5,000 IB stress relief oven

- Hydro static test bunker

- Centrifugal grinder with 24” swing and 145” grinding length

- 5” horizontal boring mill

- 100-ton horizontal press

- 48” x 144” horizontal lathe

- 55” vertical turret lathe

- IRD balancing machine

- Full-service valve and packing case repairs

proven results

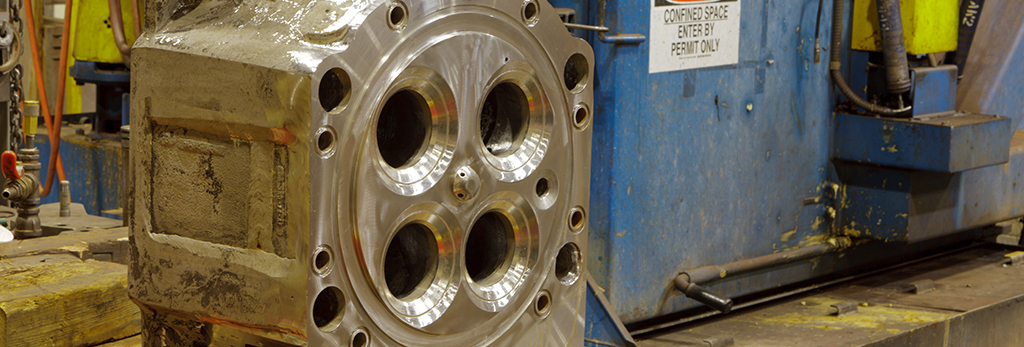

Cooper Case Study: Cooper’s Enterprise COE specializes in providing parts, service, repair, and engineering for Enterprise diesel, dual fuel, and spark ignited engines. Recently, we assisted a waste water treatment plant customer on the west coast in servicing their HVA engine. Shown in the picture is a cast steel spark ignited power head with an integral pre-combustion chamber being welded before returning to service. Our Enterprise cast steel head repairs include inspection, welding, and machining and are returned to the customer in “like new” condition with a hydrotest.

Location Information

| [email protected] | |

| Phone | +1 (713) 354-1900 |

| Address | 16250 Port Northwest Drive Houston, Texas 77041 |

| Established | 2006 |

| Property | 11.4 acres |

| Roofline | 320,000 ft2 |

| Shop | 180,000 ft2 |

| Warehouse | 100,000 ft2 |

| Office | 92,000 ft2 |

| Equipment | 20-ton cranes (5) 10-ton cranes (4) 5-ton cranes (6) |

Contacts

Vice President, Gulf Coast

Dustin Molyneaux

| Mobile | +1 (713) 354-1900 |

| [email protected] | |

Gulf Coast Sales Manager

Christopher Wilson

| Mobile | +1 (832) 541-7168 |

| [email protected] | |

Account Managers

Jimmy Baker – Fleet Sales

| Mobile | +1 (281) 201-7386 |

| [email protected] | |

Tracy Jarrell – Oklahoma

| Office | +1 (806) 228-0012 |

| [email protected] | |

Christopher Smith – Kansas

| Mobile | +1 (620) 203-8227 |

| [email protected] | |

Wade Williams – Central/North TX

| Mobile | +1 (713) 339-0627 |

| [email protected] | |

Christopher Surawski – Downstream – East

| Mobile | +1 (832) 492-7747 |

| [email protected] | |

Inside Sales

Maria Guzman – Inside Sales Manager

| Mobile | +1 (281) 253-9813 |

| [email protected] | |

Outside Sales

Arnold Mendoza Jr.

| Mobile | +1 (361) 815-6664 |

| [email protected] | |

Operations Manager

William Cook

| Mobile | +1 (979) 479-6134 |

| [email protected] | |

Warehouse Manager

Norman LeBrun

| Office | +1 (281) 809-1572 |

| Mobile | +1 (281) 387-2176 |

| [email protected] | |

Operations Team Lead

Gary Jones

| Mobile | +1 (832) 888-9100 |

| [email protected] | |

Operations Coordinator

Troy Stansel

| Mobile | +1 (713) 295-1228 |

| [email protected] | |

Senior Shop Coordinator

Cris Martinez

| Office | +1 (713) 354-1900 |

| Mobile | +1 (713) 204-7024 |

| [email protected] | |

Field Service Manager

Greg Gonzales – Gulf Coast

| Mobile | +1 (281) 770-1383 |

| [email protected] | |

Field Machining

Daryl Roberts

| Mobile | +1 (903) 267-0241 |

| [email protected] | |

Dustin Molyneaux

Vice President, Gulf Coast Region

Dustin Molyneaux brings more than 16 years of experience in the machinery manufacturing industry. Dustin’s journey began at Dresser-Rand in 2008, where he wore many hats, including Client Service Manager, Commercial Operations Manager, and Service Center Manager. Following the acquisition of Dresser-Rand by Siemens Energy in 2017, Dustin climbed the ranks holding positions such as Director of Sales – Atlantic, Director of Business Development and Digital Solution Sales, North America, and Head of Sales North America – Industrial Applications Services. By 2022, he was promoted to Head of Global Repair Operations, and in 2023, Dustin made a strategic move to Shermco Industries as VP of National Accounts. Dustin now serves as Cooper’s VP – Gulf Coast Region where he will lead our team with vision and integrity, driving growth, and fostering strong relationships across the Gulf Coast. Dustin holds a Bachelor of Economics from the University of South Florida and an MBA from Louisiana State University.