Ingersoll Rand integral

engines and compressors

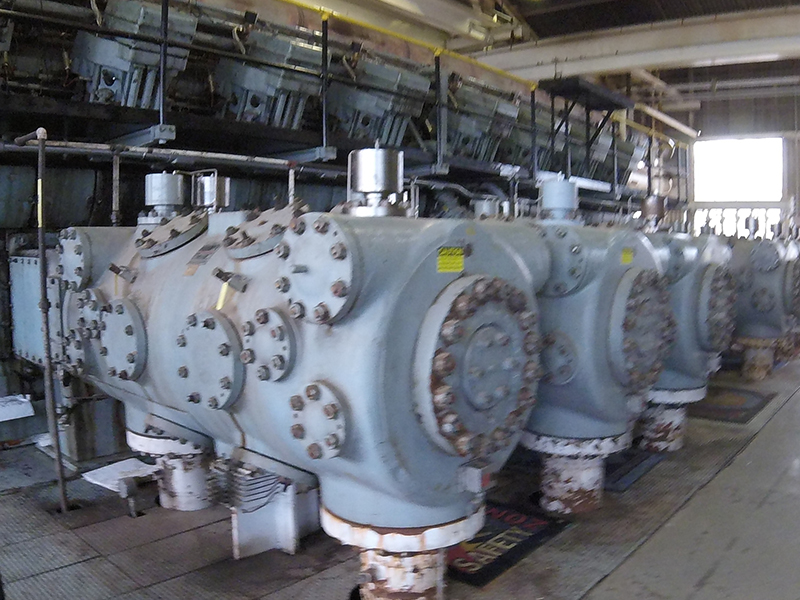

For decades, Cooper has been a complete provider of parts, service, repairs, and upgrades for Ingersoll Rand (IR) integral engine-compressors.

Cooper may not be the O.E.M. of IR Engines and Compressors, but we are proud to help our customers keep this legendary engine running in peak condition.

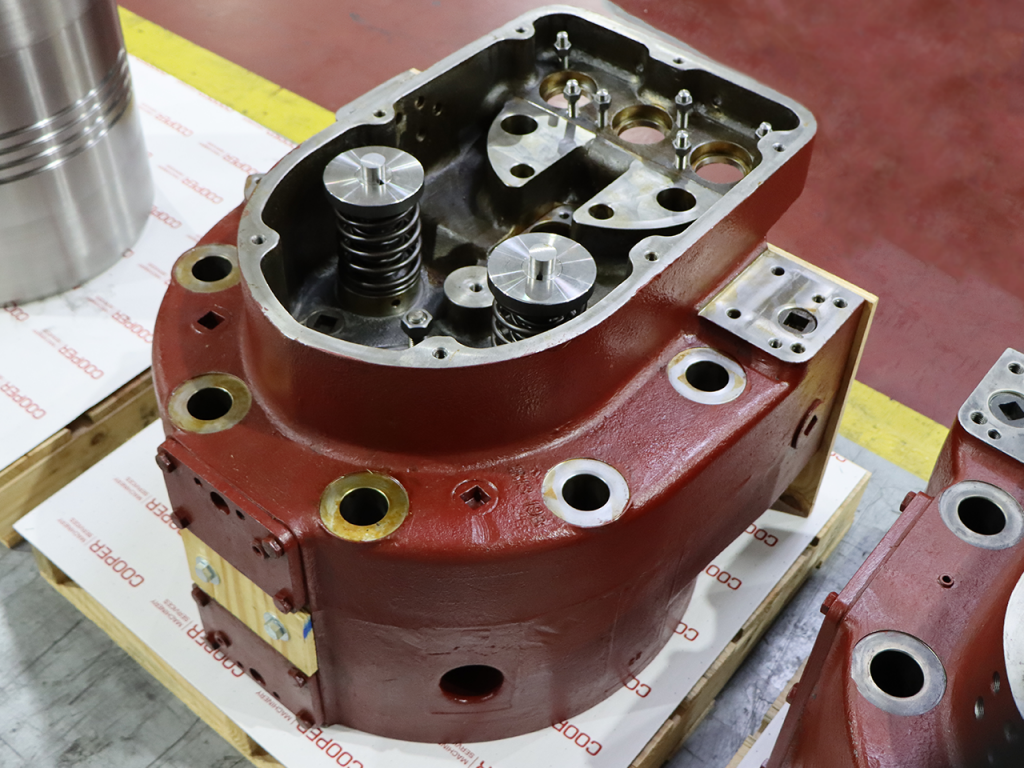

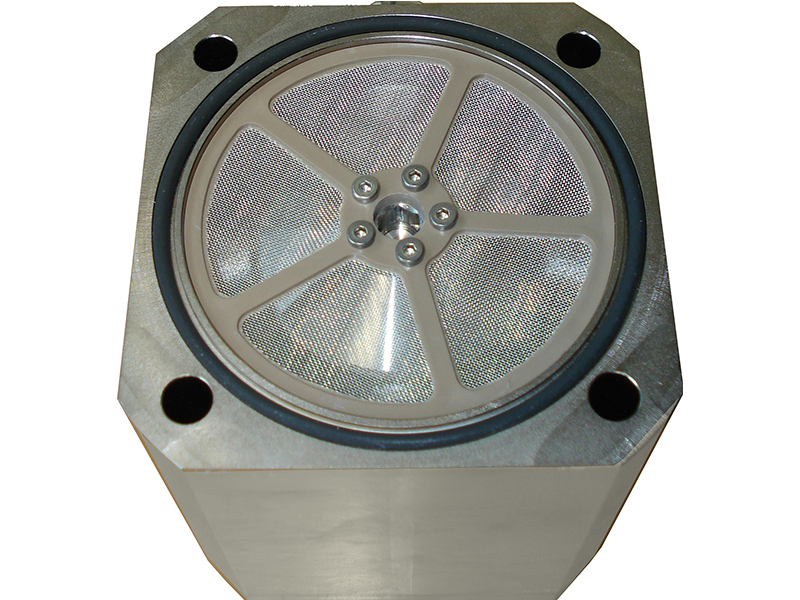

Cooper delivers a full line of O.E.M.-quality parts, service, repairs, and technical support to customers who want to keep their IR integral gas engines-compressors running in peak condition. We provide O.E.M. quality and modernized power cylinders, liners, pistons, heads, and more for your Ingersoll Rand slow-speed integrals.

Genuine Cooper parts for Ingersoll Rand engines are backed with decades of engineering, manufacturing, and in-field experience in material wear. We provide spare IR engine parts that are manufactured to the latest standards and technical advancements. From our IR manufacturing centers in Houston, Texas, we are committed to making every IR part with our own brand of O.E.M. quality and to O.E.M. standards. We are committed to stocking and delivering IR engine parts to our customers quickly and efficiently, and that’s why we house many key IR iron parts at our dedicated central distribution center in Houston, Texas and in our field locations around the world.

Cooper has provided a complete line of engine, field, and shop services for Ingersoll Rand Engines and Compressors for decades. From preventative maintenance, to shop and field overhauls, to field machining, to repairs in our many global shops, our Cooper service teams are fully trained on IR engines and stand ready to assist our customers with all their service needs.

For decades, Cooper has been providing technology and engineering services for Ingersoll Rand engines upgrades. With our advanced technologies, expertise, and project management experience, we offer IR upgrades to reduce engine emissions, increase horsepower, improve efficiencies and reliability of your equipment, and reduce maintenance costs. Upgrades include, but are not limited to, jet cell conversions, air/fuel ratio improvements, blower/turbocharger upgrades, ignition system upgrades, and electronic control panels.

To further strengthen our upgrade portfolio for IR engines , Cooper acquired HOERBIGER’s Engines Services (HES) division in 2019. Cooper now offers even more upgrade technologies including the HyperFuel System TM, HyperBalance™, HyperLogic™, ePCC™, and ePFI™. The Engine Services team offers engine emissions reduction and efficiency improvement upgrades, applicable to all types of IR integral engines.

The Houston, Texas facility is a trusted repair and field service provider and acts as Cooper’s center of excellence for Clark, IR, and Worthington product lines. It provides repair of Clark, Ingersoll-Rand, Worthington, and Cooper-Bessemer power liners, cylinders, and pistons.

The roots of Cooper’s involvement with Clark after-sale support began in 1915 when the son of an American Civil War soldier started his own auto repair and motor-rebuilding business in Ponca City, Oklahoma. Clair Nickles’ auto business grew and evolved into Nickles Industrial and expanded to include large engine repairs and manufacture of replacement parts for engine brands such as Clark, Ingersoll Rand, and Worthington. The company evolved into the nation’s largest independent manufacturer of replacement parts of large stationary gas and diesel engines. The business was sold to the Cameron International Compression Group (today’s Cooper) in 2001. For 20 years, Cooper has upheld the legacy of Clair Nickles, and today, provides owners of Clark, Ingersoll Rand, and Worthington engines a complete line of after-sales support including parts, repairs, service, and technical support.

Cooper has been providing 0.5 g/bhp-hr NOx solutions for many years to upgrade your engines to the lowest possible emissions. Numerous IR engines have been upgraded and are operating in the field at these very low NOx levels. Click here to learn more about the 0.5 g/bhp-hr solution.

| Product Model | Bore × Stroke (in) | Rated Speed (rpm) | Rated HP/Cyl (bhp) | Compression Stroke (in) |

|---|---|---|---|---|

| XVG | 11 x 12 | 350 | 41 | 12 |

| XVO | 9½ x 12 | 350 | 30 | 10½ |

| JVG | 8¼ x 9 | 550 | 30 | 9 |

| SVG | 11¾ x 12¾ | 400 | 55 | 12 |

| SVO | 11¾ x 12 | 400 | 50 | 12 |

| PGC1 | 17 x 19 | 240 | 90 | |

| XG | 18 x 20 | 220 | 100 | |

| XOG | 12 x 14 | 330 | 45 | |

| XVG | 11 x 12 | 350 | 41 | |

| KVT | 16 x 22 | 330 | 250 | 15½ |

| KVH | 16 x 22 | 330 | 282 | 15½ |

| KVR | 17 x 22 | 350 | 345 | 15½ |

| KVTR | 16 x 22 | 330 | 283 | 15½ |

| LVG | 14½ x 18 | 300 | 81 | 15 |

| KVG | 15¼ x 18 | 330 | 100 | 14 |

| KVG | 15¼ x 18 | 330 | 110 | 15 |

| KVGR | 16¼ x 18 | 330 | 137 | 15 |

| KVO | 15¼ x 18 | 330 | 137 | 15 |

| KVS | 15¼ x 18 | 330 | 167 | 15 |

| TVS | 10¾ x 13 | 450 | 89 | 11 |

| TVR | 11½ x 13 | 475 | 100 | 11 |

| SVS | 11½ x 13 | 550 | 135 | 11 |

| KVSE | 16¼ x 18 | 360 | 237 | 15 |

| KVSF | 15¼ x 18 | 330 | 167 | 15 |

| KVSR | 16¼ x 18 | 330 | 217 | 15 |

Cooper Machinery Services is an after sale provider of parts and services for INGERSOLL RAND (IR) engines and compressors. INGERSOLL RAND and IR are trademarks of Ingersoll Rand Industrial U.S., Inc.

Cooper Machinery Services and its products and services are not sponsored, authorized, or endorsed by Caterpillar, Clark, Ingersoll Rand, Waukesha, or Worthington. All non-O.E.M. product names are property of their respective owners. Any references to trademarked names are solely for informational purposes and do not constitute a claim of ownership by Cooper Machinery Services of CAT, Clark, Ingersoll Rand, Waukesha, or Worthington. CAT is a registered trademark of Caterpillar, Inc. Waukesha is a registered trademark of INNIO Waukesha Gas Engines, Inc. Ingersoll Rand is a registered trademark of Ingersoll Rand, Inc.”