OVERVIEW

AJAX Engines, the Clear Choice for Your Compression Needs.

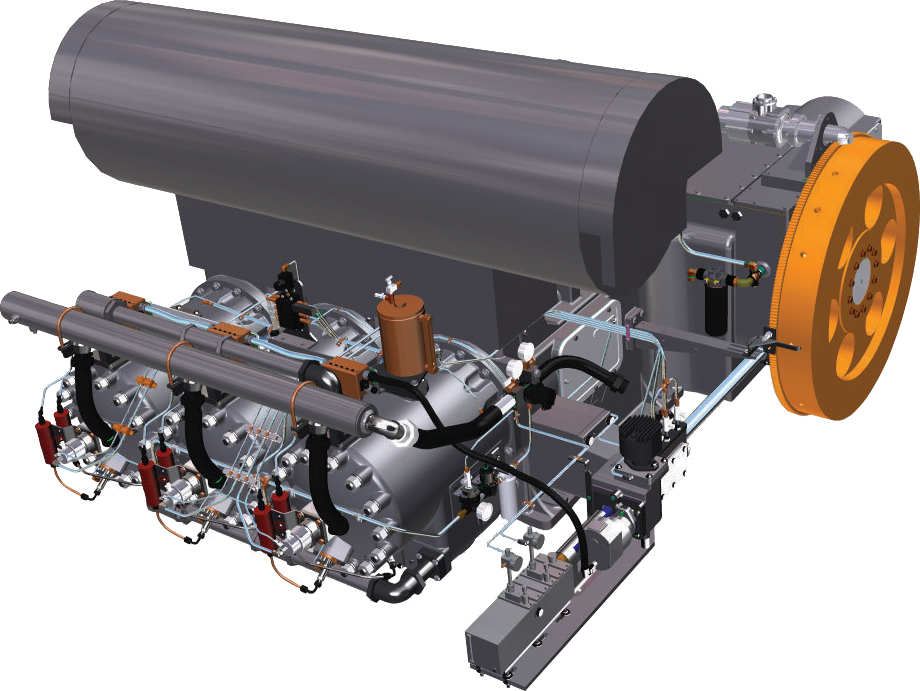

Robust, reliable AJAX engines have been manufactured in the United States longer than any other brand of compression engines. Continuous innovations and technologies add compliance, strength, and simplicity to the original design. AJAX integrals with ratings of 148 – 845 bhp (110 – 650 kWb) feature a slow-speed, two-cycle engine design that results in less wear and fewer moving parts and offers greater reliability and efficiency than high-speed separable units. As a result, operating costs are substantially lower over the life of your equipment. The AJAX integral engine-compressors are the economic choice for a variety of applications, including gas gathering, injection, processing, transmission, and fuel gas boosting.