Environmental, social, & corporate Governance

We actively care for our people, our communities and the environment.

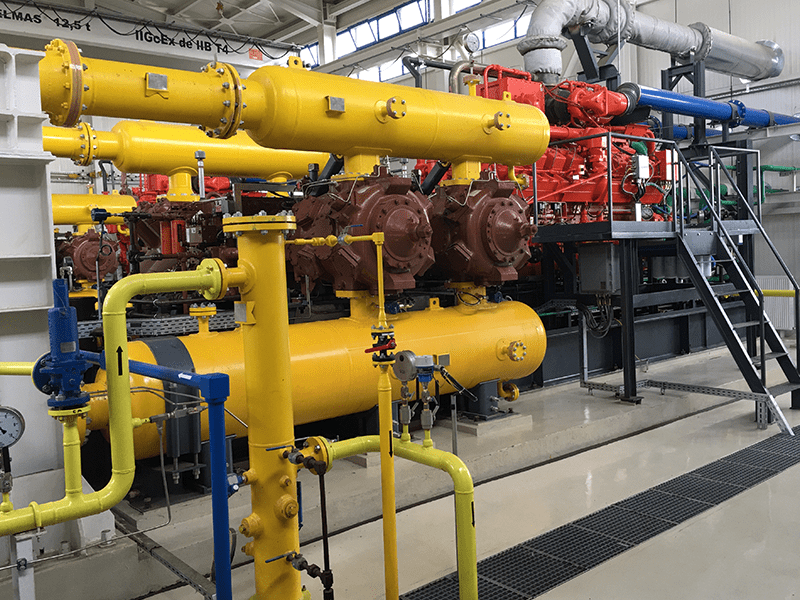

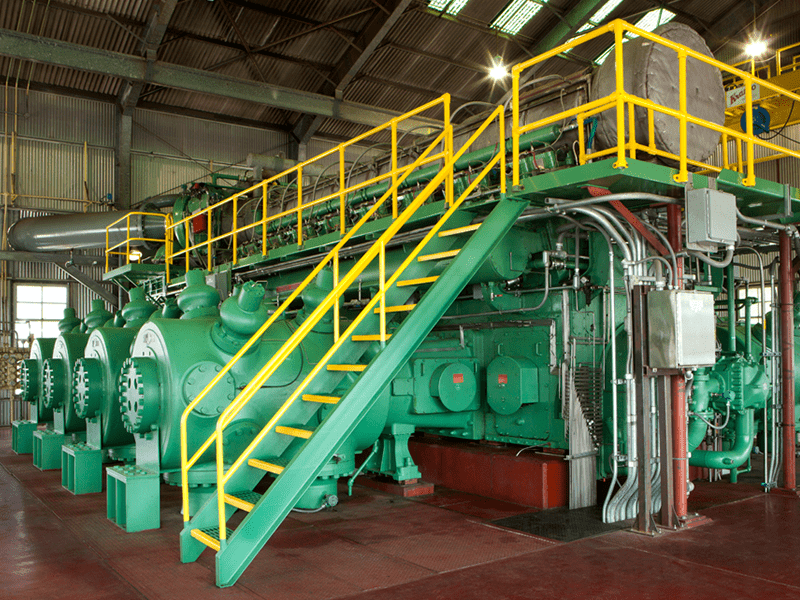

Southern Star Central Gas Pipeline, Inc. and Cooper have successfully field tested a large bore, slow-speed integral engine running on a 30% hydrogen (H2) fuel blend. The two companies modified a large bore Cooper-Bessemer GMVH-12 at Southern Star’s Hugoton, Kansas compressor station to run on a blend of hydrogen and natural gas. The engine was equipped with Cooper’s HyperBalance IV™ system to monitor pressures, collect data, and ensure equipment safety during the test.

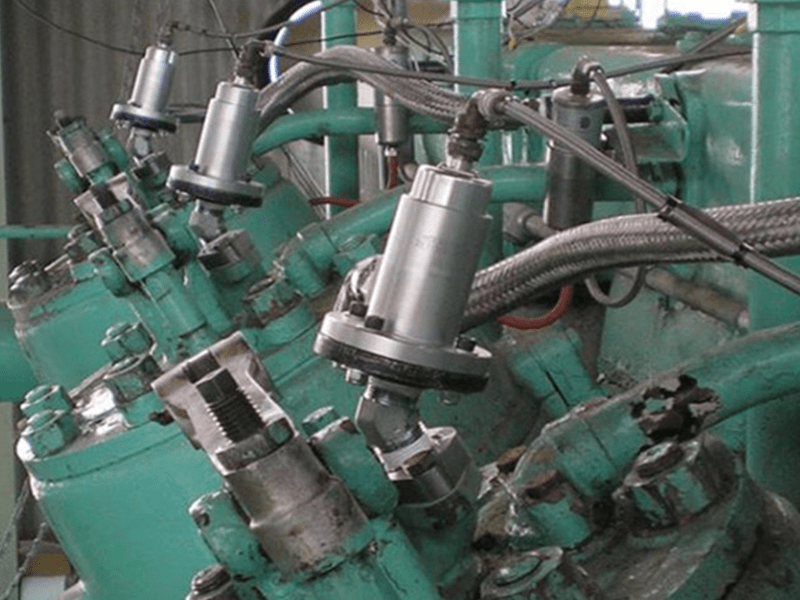

The reduction of greenhouse gases, particularly methane, is a key element of Cooper’s emissions reduction technology offering. To improve the environmental impact of engine-compressors operating within our industry, Cooper is pleased to announce CleanBurn Plus™, an emission reduction solution tailored to reduce fuel consumption, fuel slip, methane leakage, and unburned hydrocarbons.

Cooper’s CleanBurn Plus™ upgrade package is a comprehensive solution that can reduce methane output by up to 40% in most of the industry’s integral engine-compressors. For a fleet of engines rated collectively at 100,000 HP, this level of CO2 reduction can equal 20,000 tons/year, equivalent to the elimination of 4,348 standard passenger cars.

Our CleanBurn Plus™ upgrades are offered across our entire integral engine-compressor product line to include AJAX®, Cooper-Bessemer®, Clark, Enterprise®, Ingersoll Rand, and Worthington.

| Product | |||||||

|---|---|---|---|---|---|---|---|

| Cooper-Bessemer | |||||||

| Worthington | |||||||

| Cooper-Bessemer | |||||||

| Clark | |||||||

| Worthington | |||||||

| Ingersoll Rand | |||||||

| Ingersoll Rand | |||||||

| Cooper-Bessemer | |||||||

| Cooper-Bessemer | |||||||

| Clark | |||||||

| Worthington | |||||||

| Clark | |||||||

| Ingersoll Rand | |||||||

| AJAX |

* Based on 4,500 operating hours/year, 930BTU/ft3 fuel

** Average passenger car generates 4.60 Tonnes CO2e/year (U.S. EPA)

*** 1 Bbl crude oil generates 0.43 Tonnes CO2e (U.S. EPA)

**** Average U.S. home generates 8.30 Tonnes CO2e/year (U.S. EPA)

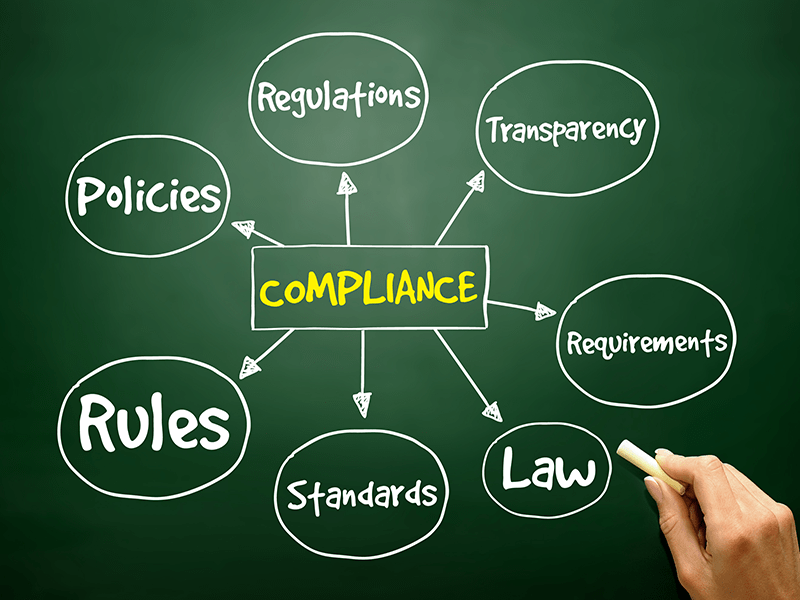

As a global company, Cooper takes its responsibility to be a good corporate citizen enthusiastically. We are proud of the way our people consistently and ethically operate with high standards in safety, quality, social responsibility, compliance, and environmental impact.

It starts on the inside. As a company, we promote a culture of always finding ways to make incremental improvements, like eliminating hazardous processes or doing more in our communities. We recently improved energy efficiency by installing automatic shutdown of unused equipment. Little things add up.

The energy industry – especially oil & gas – sometimes gets a bad rap for environmental practices. The truth is, no industry has taken bigger steps to improve care of the environment. We’re excited that products and services from Cooper are major contributors to that effort. As one example, Cooper technologies can help reduce engine NOx emissions to 0.5 g, which is far below the regulated limits in most countries.

A big part of our E.S.G. journey is helping our customers along their journey. It’s something we take very seriously, and we’re not ashamed to say that we’re really good at it. Ask us how we can help.