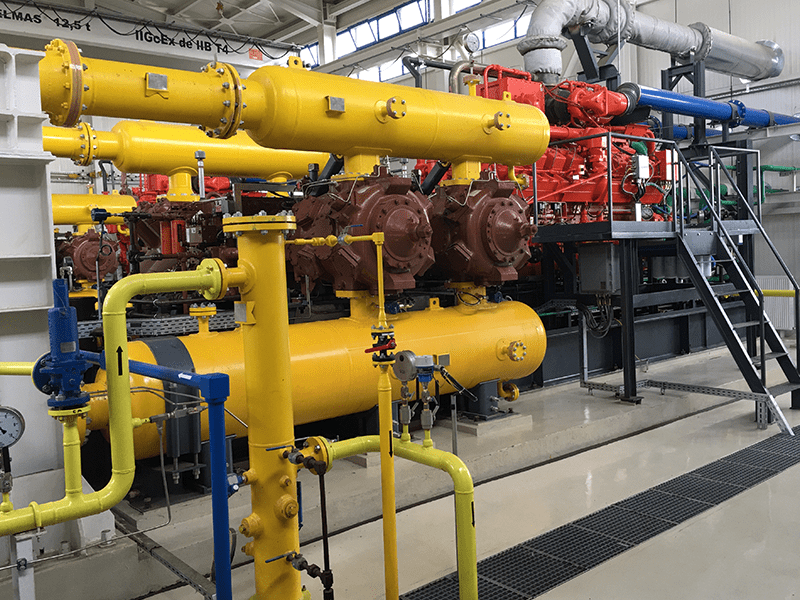

operational Efficiency

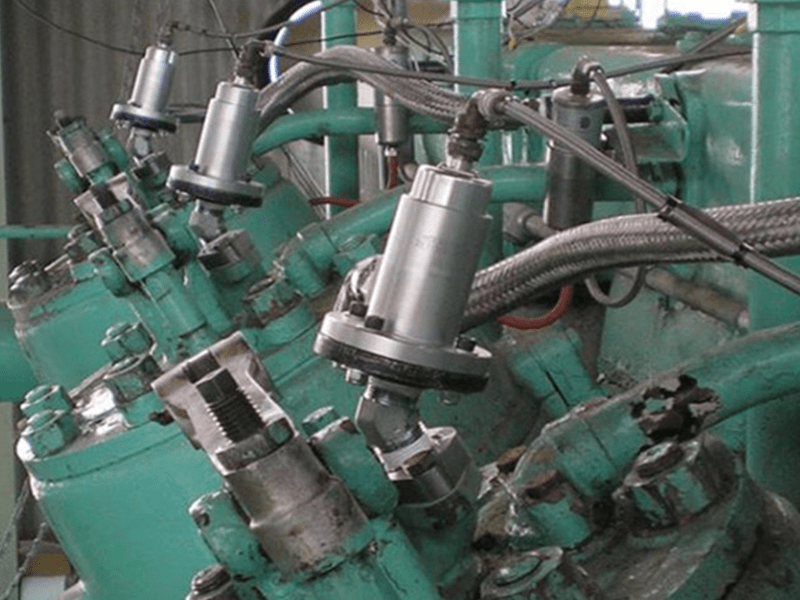

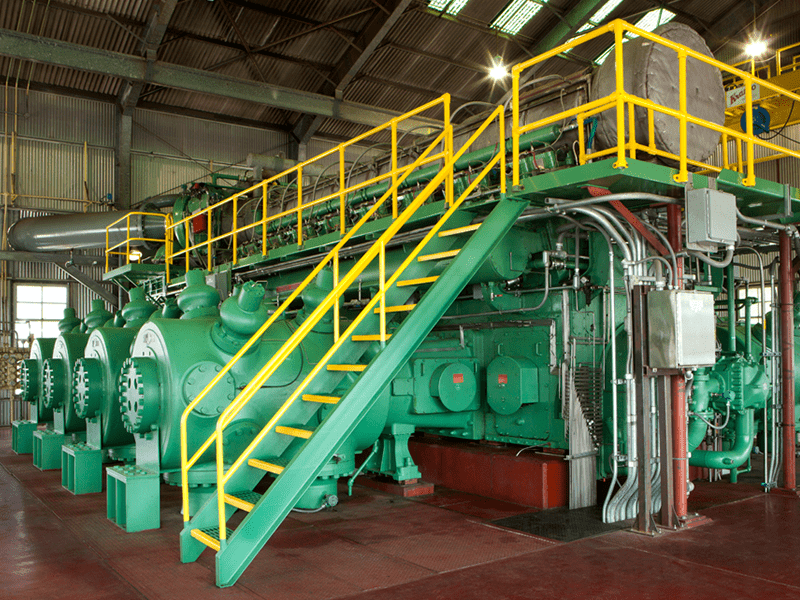

Keep your legacy equipment running while reducing your carbon footprint and greenhouse gas emissions with Cooper’s engine and compressor upgrade products.

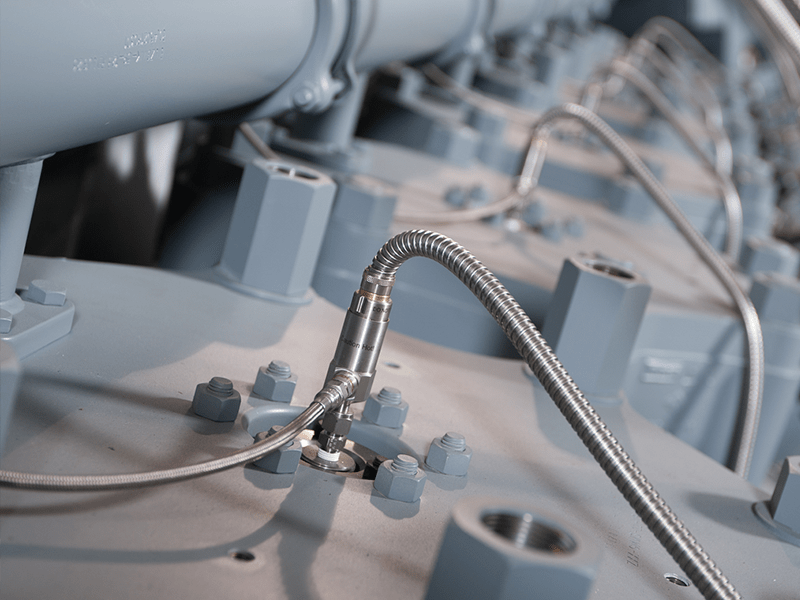

The most important strategy for keeping your legacy engines and compressors in place while reducing your carbon footprint and greenhouse gas emissions is to get your equipment operating at peak operational efficiency. A well-maintained engine will perform to its fullest potential and deliver the best fuel efficiency – using less fuel to get the same horsepower. A more fuel-efficient engine will, in turn, lead to a lower release of CO2 and other pollutants like NOx, CO and HC.

These services from Cooper help make sure your engine and compressor are always reaching their full potential.