Industry leaders in emissions reduction for nearly 5 decades

The lowering of NOx emissions is one of the most visible and talked about aspects of environmental protection. Over the last few decades, governments around the world have steadily lowered NOx thresholds, and we have responded with excellent emissions reduction solutions.

Over 40 years, Cooper has eliminated more than 3.5 MM tons of NOx using CleanBurn™ technology while reducing total hydrocarbons.

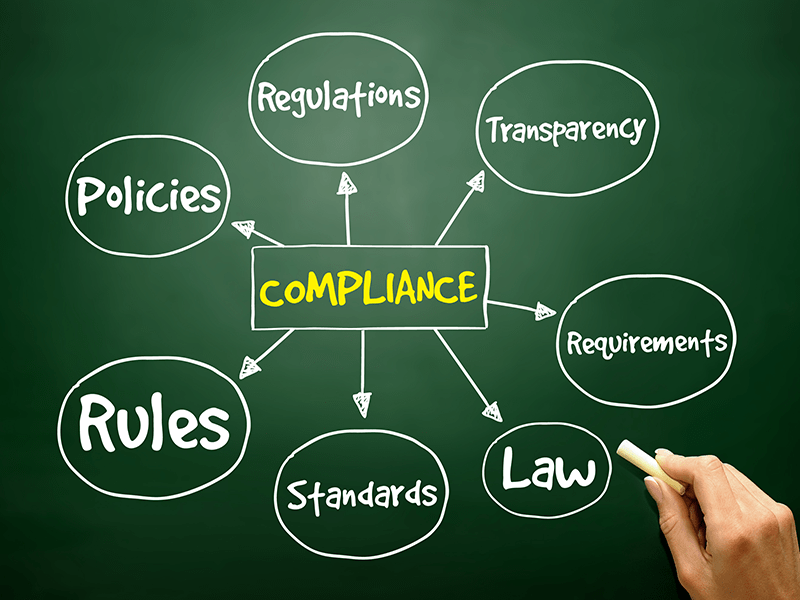

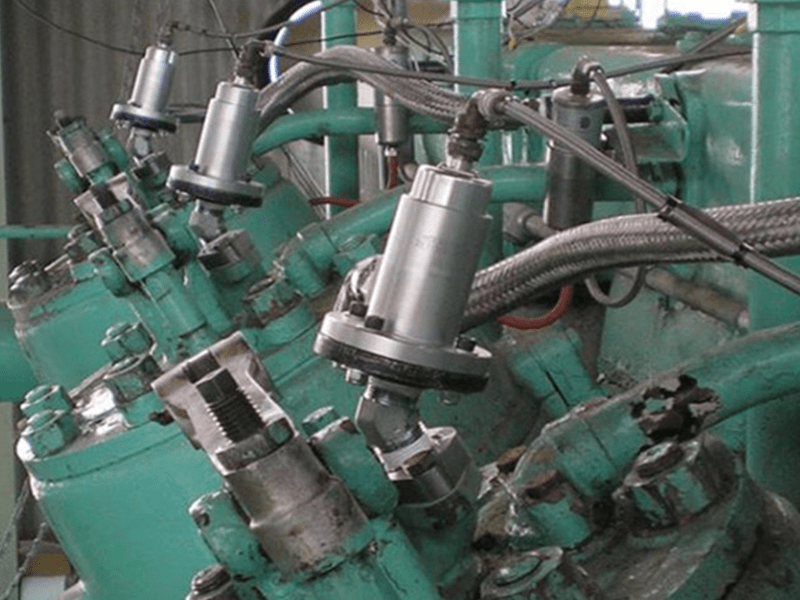

Cooper installed the first CleanBurn™ unit in 1977. This was quickly followed by the first CleanBurn™ retrofit a year later. This technology quickly became the standard for all new units. Since then, Cooper has manufactured almost 900 new units with CleanBurn™ technology. Over the years, Cooper adapted the CleanBurn™ technology to other manufacturers’ units.

| |

- 4,500 operating hours/year

- 30 years of operation for new compressors & 20 years for retrofits

- 9 gm/bhp-hr avg NOx reduction for new compressors

- 6 gm/bhp-hr avg NOx reduction for retrofits

HYDROGEN TEST ALERT

COOPER & SOUTHERN STAR Achieve hydrogen research breakthrough

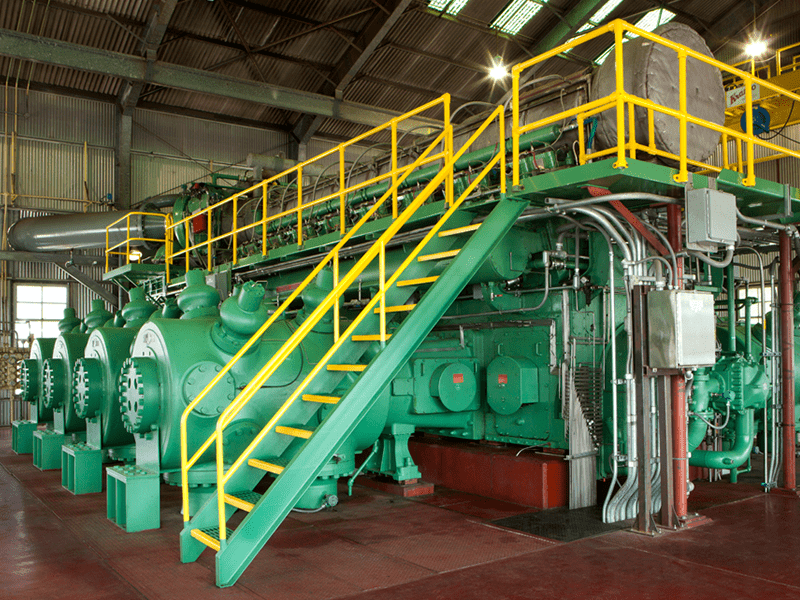

Southern Star Central Gas Pipeline, Inc. and Cooper have successfully field tested a large bore, slow-speed integral engine running on a 30% hydrogen (H2) fuel blend. The two companies modified a large bore Cooper-Bessemer GMVH-12 at Southern Star’s Hugoton, Kansas compressor station to run on a blend of hydrogen and natural gas. The engine was equipped with Cooper’s HyperBalance IV™ system to monitor pressures, collect data, and ensure equipment safety during the test.

INTRODUCING CLEANBURN PLUSTM

Reduces methane output by up to 40%

The reduction of greenhouse gases, particularly methane, is a key element of Cooper’s emissions reduction technology offering. To improve the environmental impact of engine-compressors operating within our industry, Cooper is pleased to announce CleanBurn Plus™, an emission reduction solution tailored to reduce fuel consumption, fuel slip, methane leakage, and unburned hydrocarbons.

Cooper’s CleanBurn Plus™ upgrade package is a comprehensive solution that can reduce methane output by up to 40% in most of the industry’s integral engine-compressors. For a fleet of engines rated collectively at 100,000 HP, this level of CO2e reduction can equal 20,000 tons/year, equivalent to the elimination of 4,348 standard passenger cars.

Our CleanBurn Plus™ upgrades are offered across our entire integral engine-compressor product line to include AJAX®, Cooper-Bessemer®, Clark, Enterprise®, Ingersoll Rand, Superior®, and Worthington.

| Product | |||||||

|---|---|---|---|---|---|---|---|

| Cooper-Bessemer | |||||||

| Worthington | |||||||

| Cooper-Bessemer | |||||||

| Clark | |||||||

| Worthington | |||||||

| Ingersoll Rand | |||||||

| Ingersoll Rand | |||||||

| Cooper-Bessemer | |||||||

| Cooper-Bessemer | |||||||

| Clark | |||||||

| Worthington | |||||||

| Clark | |||||||

| Ingersoll Rand | |||||||

| AJAX |

* Based on 4,500 operating hours/year, 930BTU/ft3 fuel

** Average passenger car generates 4.60 Tonnes CO2e/year (U.S. EPA)

*** 1 Bbl crude oil generates 0.43 Tonnes CO2e (U.S. EPA)

**** Average U.S. home generates 8.30 Tonnes CO2e/year (U.S. EPA)

CleanBurn PlusTM Methane Reduction & 0.5 g/bhp-hr NOx Solution

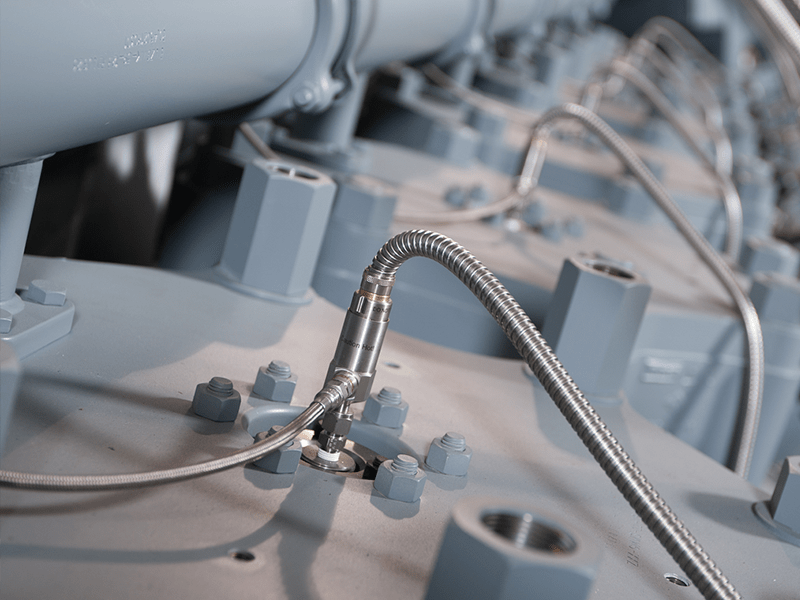

Cooper is proud to offer CleanBurn PlusTM for methane/CO2 reduction and a complete engine upgrade solution for 0.5 g/bhp-hr NOx emission that is available for all Clark, Cooper-Bessemer, and Ingersoll Rand slow-speed engine models. This emissions reduction solution has been implemented on numerous engines in field operation and is fully backed by Cooper’s guarantee.

Aftertreatment

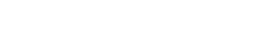

E.S.G. at Cooper

E.S.G. Journey

Environmental

Social

Governance

Helping Our Customers with their journey

Hydrogen & Landfill Gases

Equipment Upgrades

Operational Efficiency

Unburned Fuel Emissions

& Exhaust Leaks

Emissions Reduction

DOWNLOADS

- Cooper Expands After-Sales Support Offerings | Gas Compression Magazine, August 2021 , Page 16

- Cooper Shifts ESG Push into High Gear | ESG Review, First Quarter 2022, Pages 10 – 13

- Hydrogen Natural Gas Fuel Blend Lowers Emissions for AJAX Integral Engine-Compressor | ESG Review, March 30, 2022

- Cooper Integral Engine-Compressor Burns 30% Hydrogen by Volume | Gas Compression Magazine, October 2022, Pages 32 and 34