Hydrogen & landfill gases

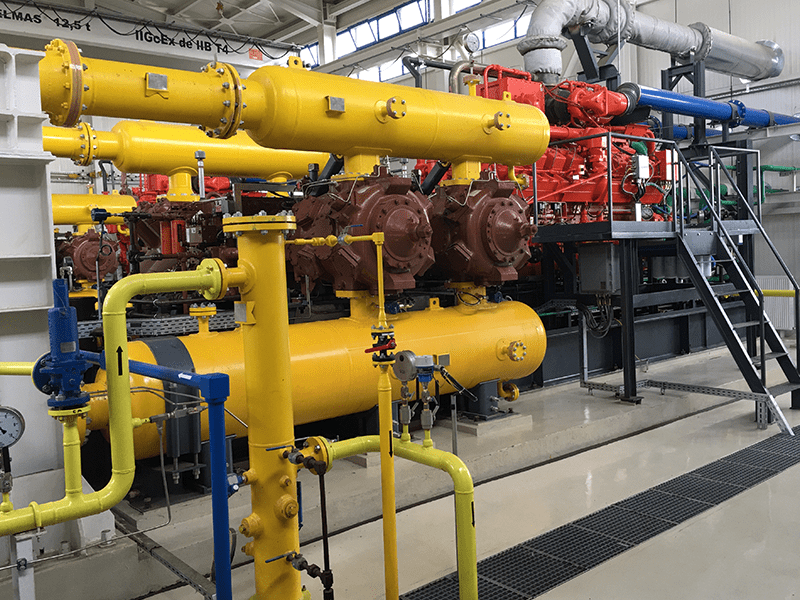

Cooper maintains a long-standing expertise and history in renewable energy.

The addition of hydrogen to the combustion of other fuels is an exciting approach to lowering emissions. Cooper can adapt your slow-speed integral engine compressor to run on up to 10% hydrogen mixed with natural gas. Contact us to learn what we can do to enable your engine to run on hydrogen.

In October 2022, Cooper and Southern Star Central Gas Pipeline, Inc. (Southern Star), a U.S.-based interstate natural gas pipeline company, announced the signing of a memorandum of understanding (MOU) to launch a joint hydrogen research project aimed at converting Southern Star’s fleet of gas fired reciprocating integral engines to combination gas-hydrogen fired units.

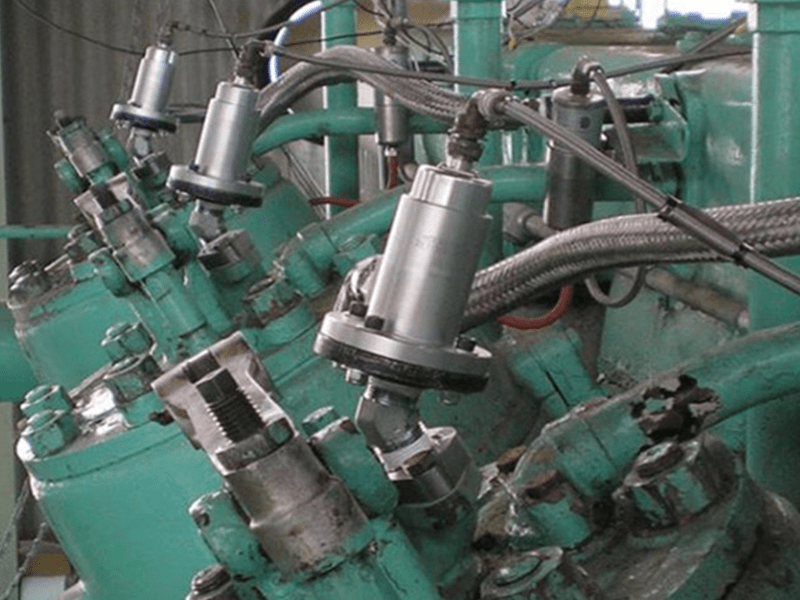

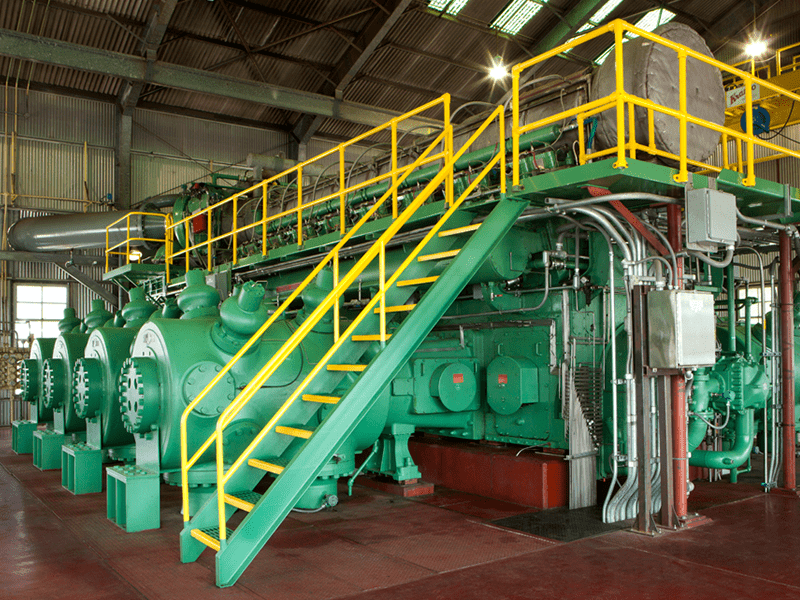

Southern Star Central Gas Pipeline, Inc. and Cooper have successfully field tested a large bore, slow-speed integral engine running on a 30% hydrogen (H2) fuel blend. The two companies modified a large bore Cooper-Bessemer GMVH-12 at Southern Star’s Hugoton, Kansas compressor station to run on a blend of hydrogen and natural gas. The engine was equipped with Cooper’s HyperBalance IV™ system to monitor pressures, collect data, and ensure equipment safety during the test.

Hydrogen is a clean fuel used most frequently in transportation and power generation applications. Hydrogen is typically produced at relatively low pressures and must be compressed prior to transport. Reciprocating compressors are the most commonly used compressors for applications that require very high compression ratios.

Cooper has been providing compressors for hydrogen compression and storage for decades. Many Superior and Cooper Bessemer hydrogen compressors are installed around the world, in countries like Iraq, Costa Rica and USA.

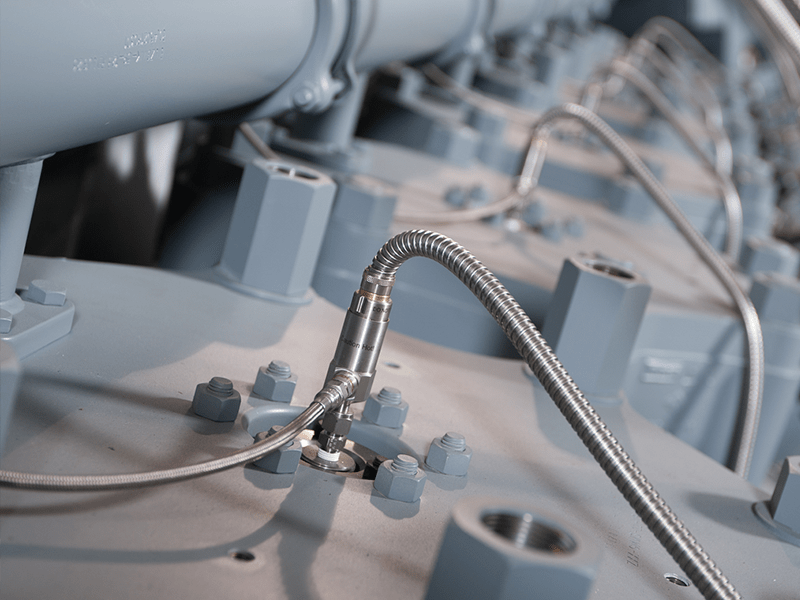

Hydrogen trim is available for every Superior compressor model including CFA, RAM, CFR, CFH, MH, WH and WG. The trim Includes a Type 3 distance piece, oil slinger, 17-4PH SS piston rod with tungsten carbide coating in the packing travel area, valves with sour gas trim, purged-type packing and cylinder testing with helium.

Biogas is a type of biofuel that is naturally produced from the decomposition of organic waste either in a landfill or a biogas digester at a sewage treatment plant. Microorganisms break down the organic material in a digestion chamber and convert it into biogas.

For decades, Cooper compressors have been used to gather and boost biogas. In the 1970s, a Cooper-Bessemer GMVH integral engine-compressor was deployed in Staten Island for a biogas boosting application. More recently, Superior RAM and CFR compressors have been used for biogas boosting in Arizona.

Cooper has also been at the forefront of power generation with biogas as fuel. Our Cooper-Bessemer LSV-B engines have been in service for decades in an Orange County, California, sanitation district for combined heat and power (CHP). Similar engines have long been deployed in the Nassau County, New York, sanitation district for power generation. Our Superior engines are commonly used for biogas applications.