Unburned fuel emissions

& Exhaust leaks

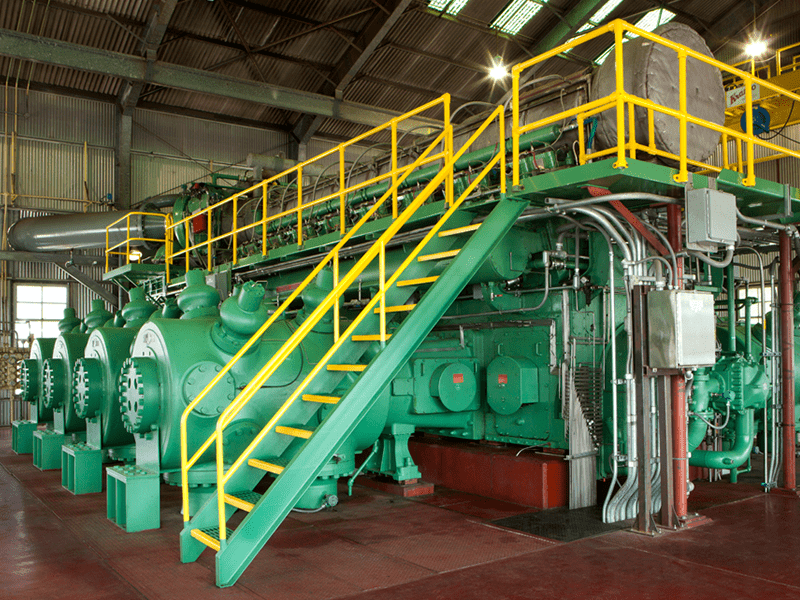

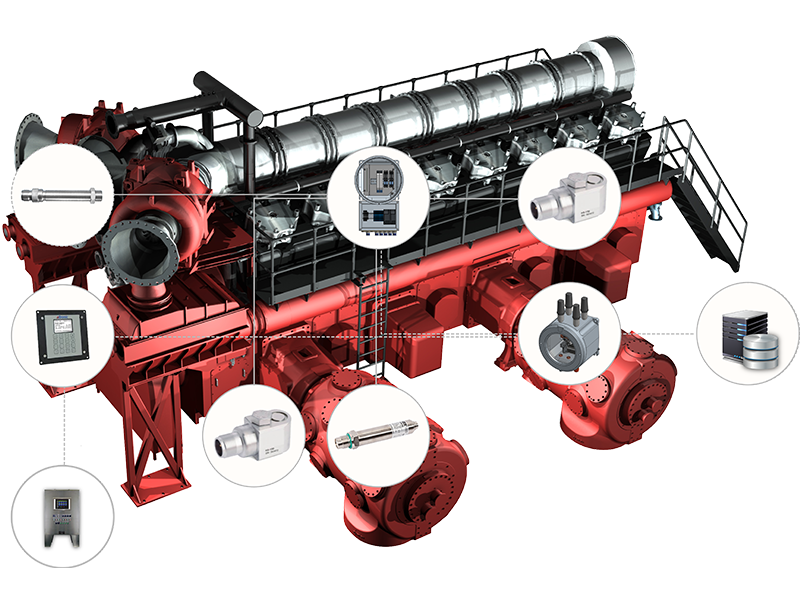

Cooper offers upgrades and solutions for engine misfire detection.

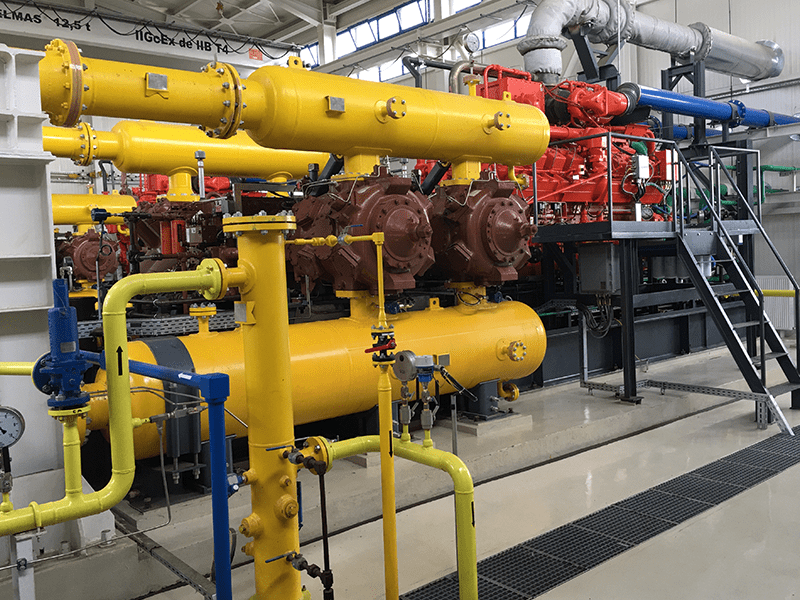

Engine fire problems may continue unnoticed and undiagnosed and lead to significance methane and hydrocarbon (HC) emissions in exhaust from the unburned fuel. Furthermore, it can also damage the catalytic converter if an aftertreatment has been deployed to reduce emissions. Cooper offers solutions for engine misfire detection.

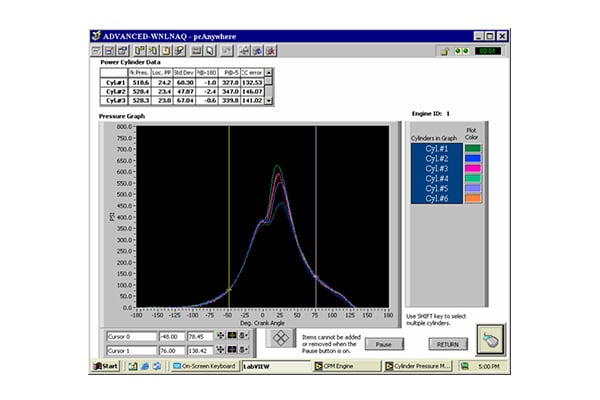

The HyperBalance IV uses pressure data from the pressure sensors to detect misfires or incomplete combustion. The misfires are tracked from time and a fault can be generated or shutdown can be initiated if the power cylinder is deemed to misfire consistently.

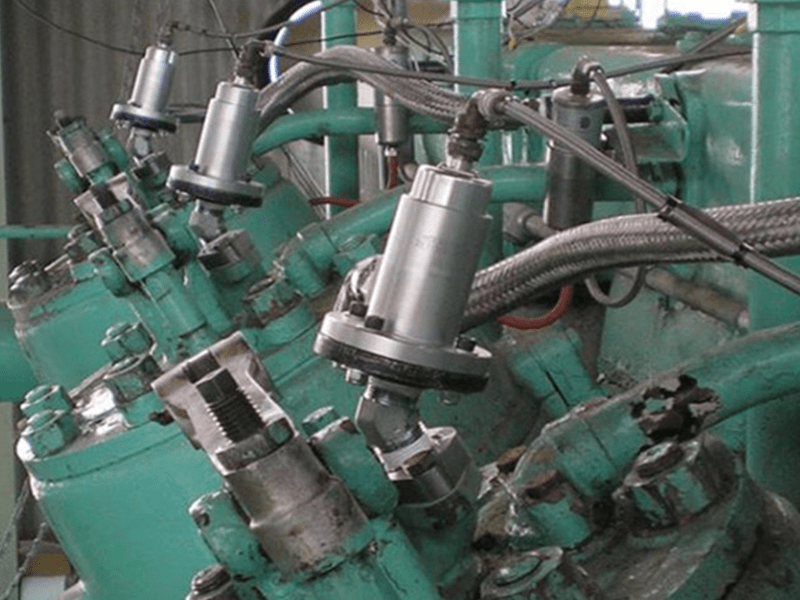

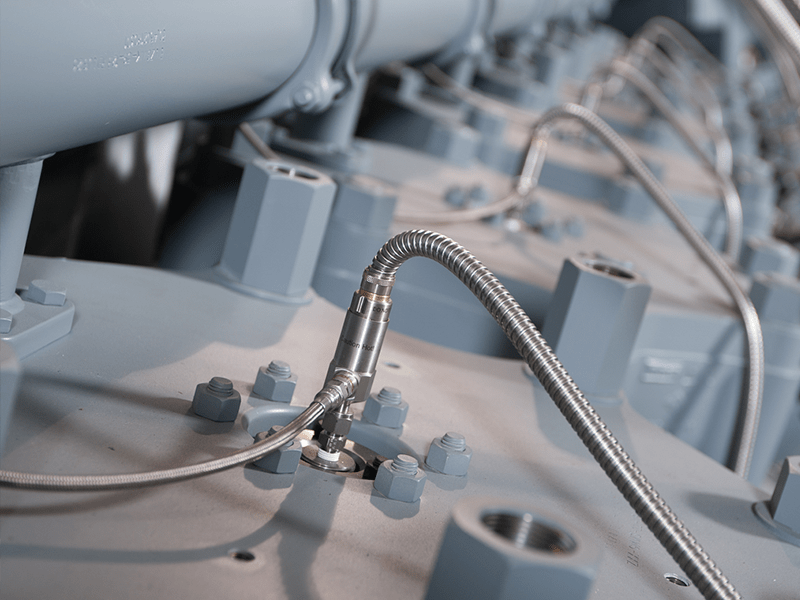

A primary function of engine piston rings is to seal the combustion chamber from the crankcase. If combustion gases slip past the rings, they can enter the crankcase, accelerating lubricant deterioration and bypassing exhaust gas treatment unless routed back to the intake. Poorly sealing rings reduce compression and fuel efficiency.

Piston rings typically require a break-in period as surface irregularities wear down and sealing improves. Over time, normal wear increases the ring end gap, leading to greater gas leakage, higher oil consumption, and reduced efficiency—eventually requiring replacement.

Cooper’s Mo2 rings address these challenges with a dual-purpose coating that shortens break-in time and slows long-term wear, delivering a more effective seal and longer service life than conventional ring coatings.