Environmental, social, & corporate Governance

The Core of Cooper's E.S.G. journey

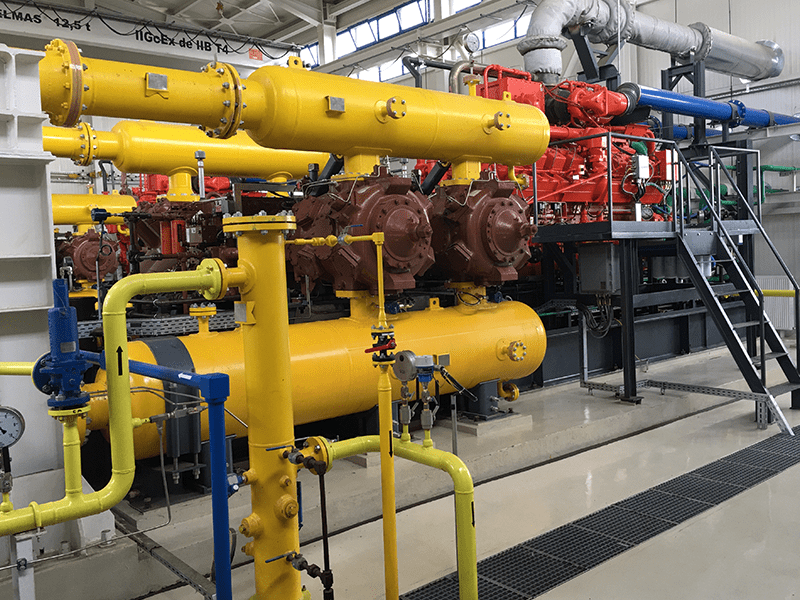

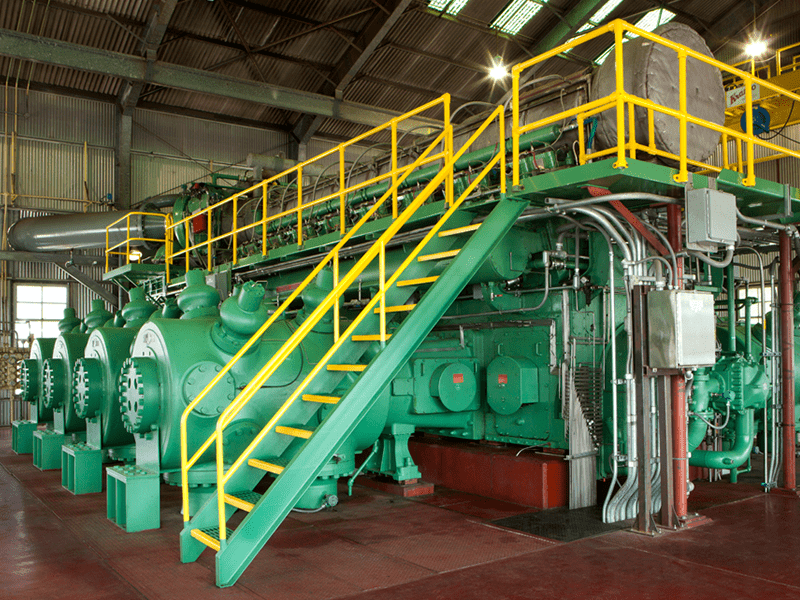

Southern Star Central Gas Pipeline, Inc. and Cooper have successfully field tested a large bore, slow-speed integral engine running on a 30% hydrogen (H2) fuel blend. The two companies modified a large bore Cooper-Bessemer GMVH-12 at Southern Star’s Hugoton, Kansas compressor station to run on a blend of hydrogen and natural gas. The engine was equipped with Cooper’s HyperBalance IV™ system to monitor pressures, collect data, and ensure equipment safety during the test.

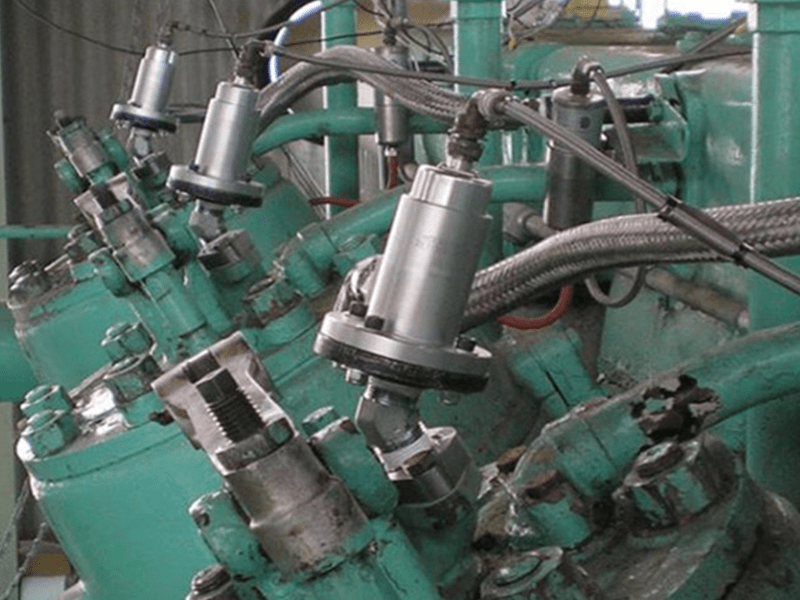

The reduction of greenhouse gases, particularly methane, is a key element of Cooper’s emissions reduction technology offering. To improve the environmental impact of engine-compressors operating within our industry, Cooper is pleased to announce CleanBurn Plus™, an emission reduction solution tailored to reduce fuel consumption, fuel slip, methane leakage, and unburned hydrocarbons.

Cooper’s CleanBurn Plus™ upgrade package is a comprehensive solution that can reduce methane output by up to 40% in most of the industry’s integral engine-compressors. For a fleet of engines rated collectively at 100,000 HP, this level of CO2 reduction can equal 20,000 tons/year, equivalent to the elimination of 2,000 standard passenger cars.

Our CleanBurn Plus™ upgrades are offered across our entire integral engine-compressor product line to include AJAX®, Cooper-Bessemer®, Clark, Enterprise®, Ingersoll Rand, and Worthington.

| Product | |||||||

|---|---|---|---|---|---|---|---|

| Cooper-Bessemer | |||||||

| Worthington | |||||||

| Cooper-Bessemer | |||||||

| Clark | |||||||

| Worthington | |||||||

| Ingersoll Rand | |||||||

| Ingersoll Rand | |||||||

| Cooper-Bessemer | |||||||

| Cooper-Bessemer | |||||||

| Clark | |||||||

| Worthington | |||||||

| Clark | |||||||

| Ingersoll Rand | |||||||

| AJAX |

* Based on 4,500 operating hours/year, 930BTU/ft3 fuel

** Average passenger car generates 10 Tons CO2e/year (EPA)

Cooper created better products and eliminated hazardous chrome- and tin-plating processes by developing new plating processes for our power pistons and cylinders. Chrome plating is hazardous for the environment, uses toxic acid baths and produces hazardous byproducts, which may cause various health conditions and pollution risks. Similar concerns apply to tin plating.

We eliminated chrome plating by introducing electrolytic hard iron plating to protect and restore power cylinders. It works better and it’s far safer. And our chrome plating of power cylinders allows the customer to repair his cylinders and avoid the expensive and environmentally costly process of attaining newly built parts.

We completely replaced tin plating with dual-coated manganese phosphate and graphite technology for protection of power pistons. This is also a much better process.

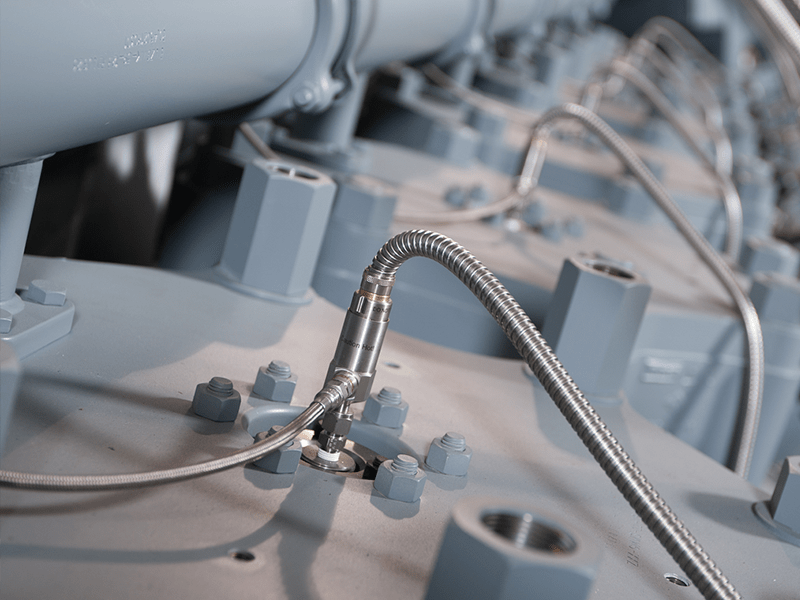

Disposal of worn-out engine or compressor parts or outdated compressor packages can be costly and a significant drain on the environment. And building new ones can be even more expensive and detrimental. In order to reduce the environmental impact, repairing parts and repurposing of old compressor packages is the right choice. Cooper is committed to helping our customers extend the life of their equipment and bringing environmentally sustainable solutions to the market.

Besides the environmental impact, component repair and equipment refurbishment also provide our customers significant savings. We inspect and evaluate used cores and remanufacture them to our exacting standards. We operate numerous service locations in the United States and worldwide, each staffed by experienced personnel and equipped to restore parts for all makes of large reciprocating engines and compressors.

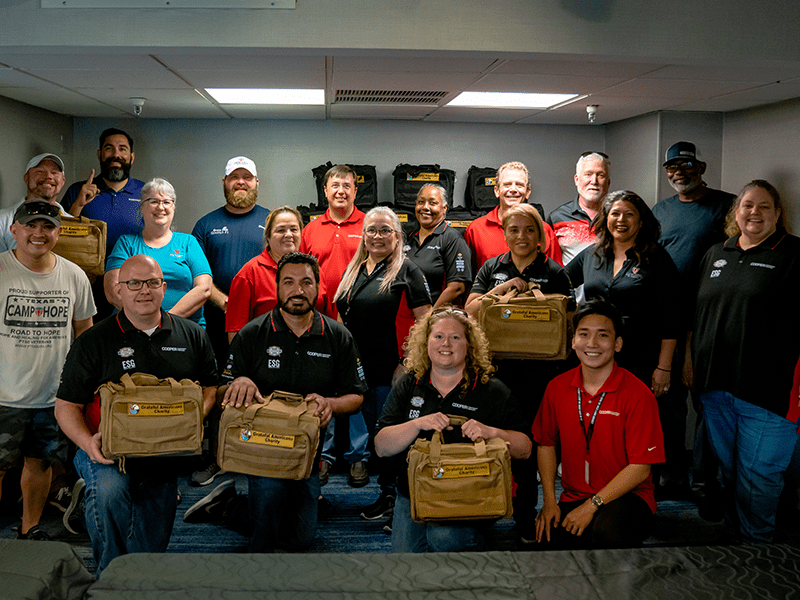

The safety of our employees and customers, the health of our environment, and the protection of the public are all core values at Cooper. We are committed to delivering the best quality and safest products and services in the industry.

Our zero-injury culture drives every element of our business. Training, prevention, policies, procedures, feedback and continual improvement are all keys to maintaining safety as one of our key metrics.